Average Value Of Fracture Toughness Is Given For A Ceramic

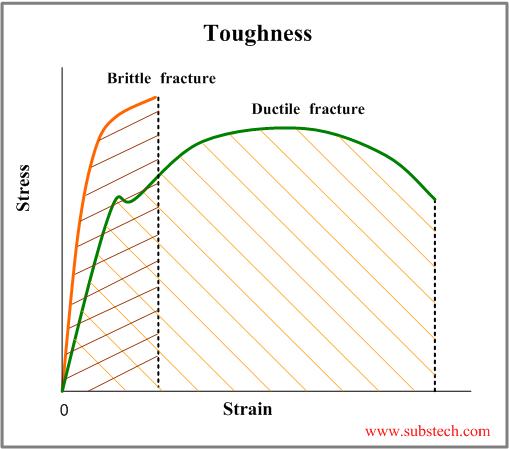

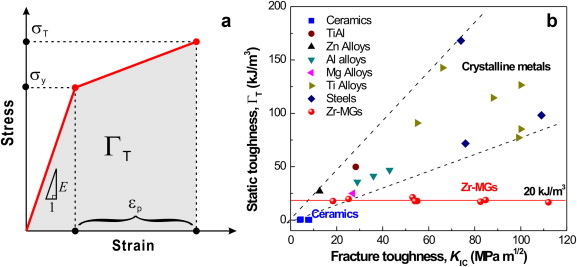

Quinn national institute of standards and technology 100 bureau drive gaithersburg md 20899 8529 abstract fracture toughness is an important property that characterizes a material s brittleness or resistance to fracture.

Average value of fracture toughness is given for a ceramic. Fujiievaluation of fracture toughness for ceramic materials by a single edge precracked beam method. Fracture toughness is a quantitative way of expressing a material s resistance to crack propagation and standard values for a given material are generally available. Is ability of material to resist fracture when a crack is present. For the pb scf and fatigue methods the precrack length is plotted.

In the present work the tensile strength is fitted using the p max a e curves from the average value of 30 and 27 specimens for porosities of 83 and. The general factors affecting the fracture toughness of a material are. A critical review george d. The ϕ value varies moderately with this increase 0 81 for si 3 n 4 30 sic 3 mgo and 0 71 for sic 50 zrb 2 10 b 4 c.

Fracture toughness testing and prediction for ceramic materials using in large flow rate emulsion pumps table 3. Material average p f n average maximum bending stress mpa average kic mpa m 1 2 zro2 1 359 2 336 12 18 zro2 2 154 2 n a 16 35. Stress intensity factor k is a. Nanoindentation based fracture toughness measurements of ceramic materials like silicon carbide sic with pyramidal indenters are of significant interest in materials research.

Fracture toughness of ceramics by the vickers indentation crack length method. 49 ran li et al. Temperature strain rate presence of structure defects and presence of stress concentration notch on the specimen surface stress intensity factor k is a quantitative parameter of fracture toughness determining a maximum value of. The general factors affecting the fracture toughness of a material are.

A majority of currently used fracture toughness models have been developed for vickers indenters and are limited to specific crack geometries. Temperature strain rate presence of structure defects and presence of stress concentration notch on the specimen surface. Slow self sustaining crack propagation known as stress corrosion cracking can occur in a corrosive environment above the threshold k iscc displaystyle k text iscc and below k ic displaystyle k text ic. Fracture toughness measured after fatigue precracking compared to fracture toughness values via c 1421.

Tested average results of each test specimen for the three ceramic materials. Thus for a given material the greater the extent of the produced cracks the lower the calculated. These equations were based on previously collected fracture toughness data for different types of ceramic materials and correlate the crack size elastic modulus and vickers hardness of the material in order to give a fracture toughness value. It is necessary to emphasize the increase in the fracture toughness of ceramic particulate composites with test temperatures.