Aramid Fiber Vs Ceramic Brake Pads

Which disc brakes are better steel or carbon ceramics.

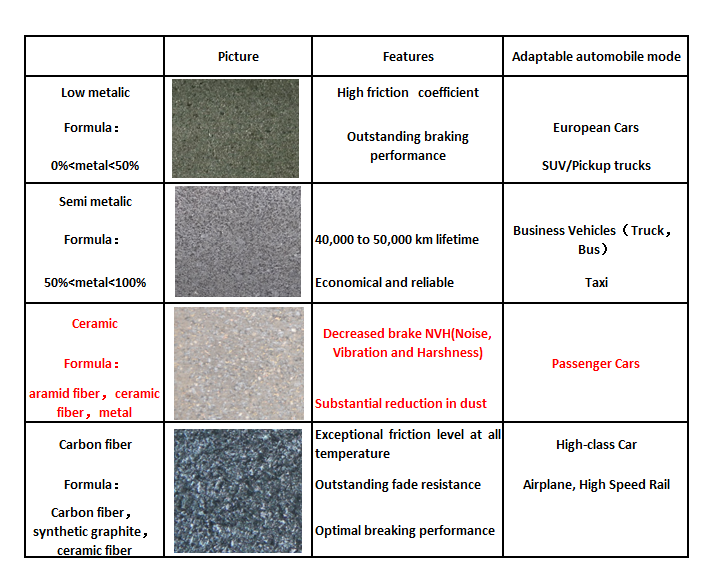

Aramid fiber vs ceramic brake pads. The unique physical properties of twaron pulp set it apart from conventional friction product ingredients. Para aramid composites brake pads. Braking response is linear no matter what the brake temperature. Para aramid vs ceramic brake pads para aramid aramid 2 kevlar twaron pad compounds began arriving in the 1990s to address these problems.

Let s start with steel brakes. However ceramic brake pads are generally a term for a group of pads known as nao or non asbestos organic pads and ebc brakes was of course the pioneer of this technology back from its early roots 70 years ago when it was part of the bba group and manufactured products known as top dog in the uk. With its superior strength and durability twaron is a high quality additive that supports radically to reduce noise vibration and harshness nvh in brake pads and brake linings. I think what you are trying to ask is.

A comparison of heat range shows both kevlar and ceramic pads to have a higher tolerance to heat then the factory semi metallic pads. There are advantages and disadvantages to both. Made up of para aramid and steel this is still considered to be a semi metallic pad but the higher concentration of para aramid significantly reduced noise. The purpose of this paper is to investigate the friction coefficients of aramid and acrylic fibers on brake pads fiber components used in the present pads are aramid and acrylic fibers respectively while keeping other components such as binders lubricants abrasives fillers the same.

These aramid fibers used in ceramic brake pads. Steel brakes are more gentle than carbon ceramics and easier to use in ev. Ceramic brake systems in automotive applications do not generally use brake pads made in ceramic material. These pads are positive molded to provide uniform density for uniform friction.

However while the kevlar pad does show an improvement in resistance to brake fade brought on by heat it does not have the resistance to extreme heat and does not recover from that heat as fast as the ceramic pads. The ebc greenstuff 6000 7000 would be recommended for heavier towing 12000 lbs towing as they are reinforced pads and will have even lower brake fade. They are aramid ceramic and or aramid metallic pads that can handle higher heat and will not glaze over under heavy towing applications. Disk fc25 and disk fc17 are used for rotor rubbing test to investigate the friction coefficients.

What are the best brake pads in 2020.