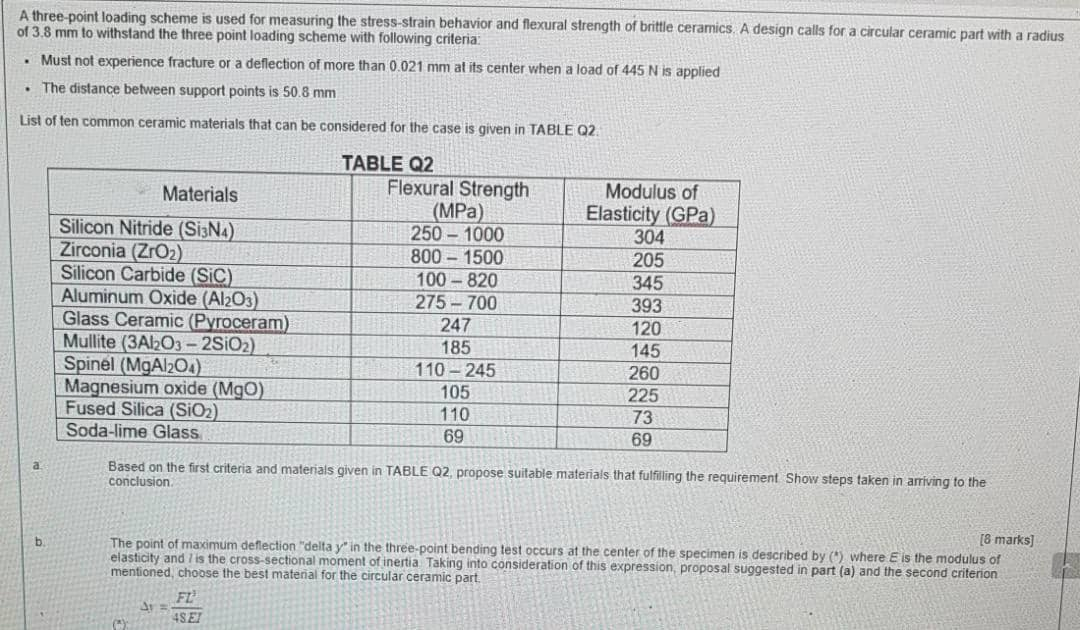

An Engineering Ceramic Has A Flexural Strength

The cross head speed in flexural test normally varies within the range 0 0040 4 inch min 0 1 10 mm min.

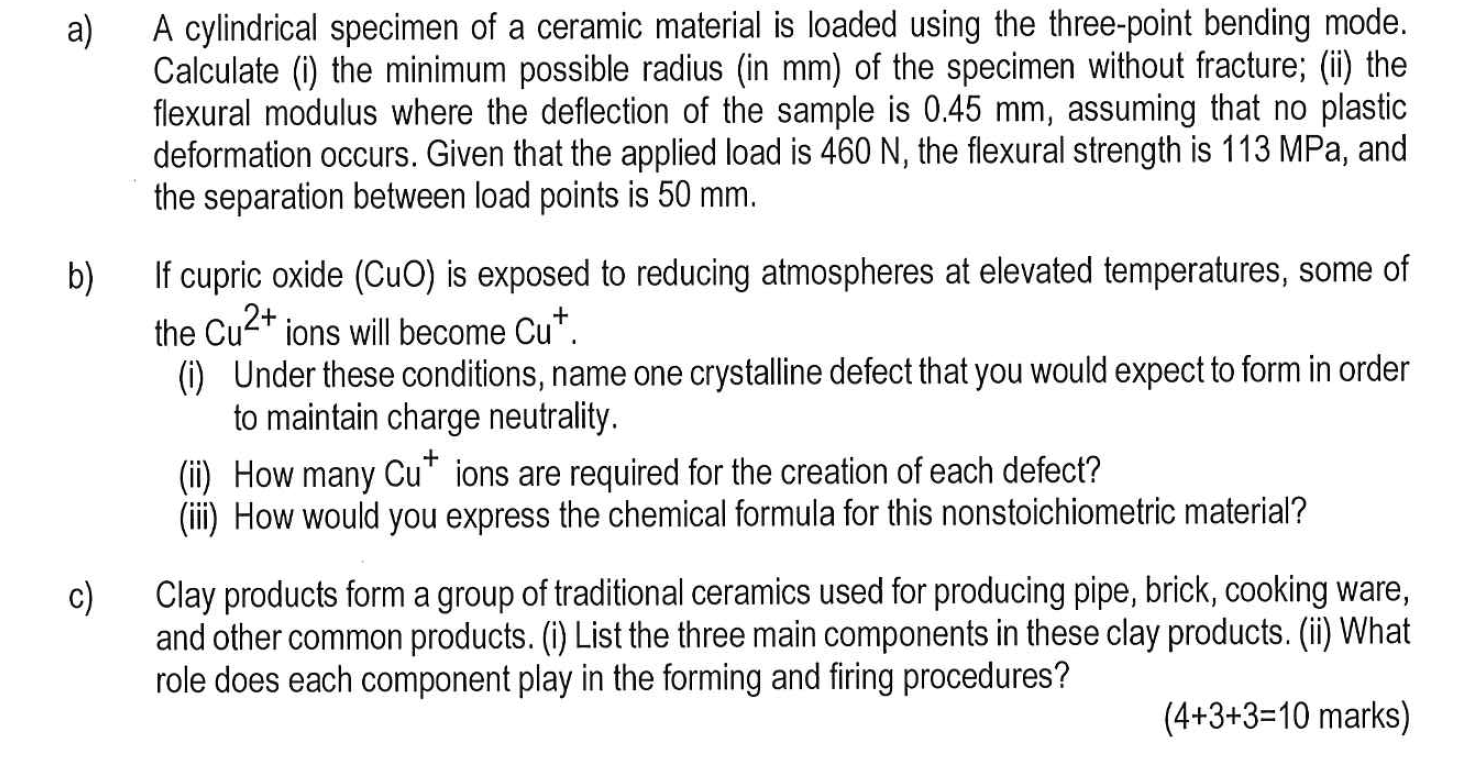

An engineering ceramic has a flexural strength. Amorphous structure means that atoms are not organized according to a well ordered repeating arrangement as in crystals. Flexural strength also known as modulus of rupture or bend strength or transverse rupture strength is a material property defined as the stress in a material just before it yields in a flexure test. Glass ceramics are made of small grains surrounded by a glassy phase and have properties in between those of glass and ceramics. The picture to the left shows a bar of technox 2000 300 x 12 x 4mm being tested and which is deflecting 4 5mm at its centre.

What is the level of flexural strength if the probability of failure has to be 0 1 discuss the effect of strain rates and temperature on ductile to brittle fracture transitions. The flexural strength of a material is defined as the maximum bending stress that can be applied to that material before it yields. Modulus of rupture flexural strength is the stress of the extreme fiber of a specimen at its failure in the flexure test. Speeds 1 mm min and 0 1 min 2 54 mm min are mostly used in the tests.

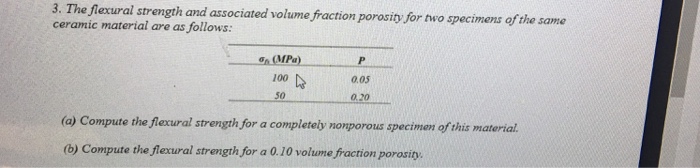

For full table with tesnsile strength compressive strength flexural strength and modulus of elasticity rotate the screen. Flexural strength is calculated by the formula. An advanced engineering ceramic has a weibull modulus of m 9. Flexural strength calculation.

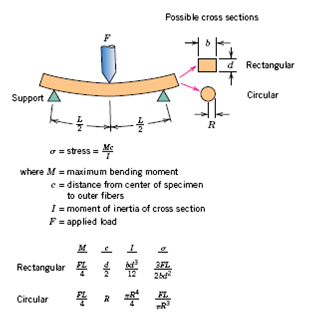

Expert answer 100 1 rating related questions. The transverse bending test is most frequently employed in which a specimen having either a circular or rectangular cross section is bent until fracture or yielding using a three point. Flexural testing is the most common method used to measure the uniaxial tensile strength of ceramics and glasses. Flexural strength in ceramic materials is usually measured by breaking test bars or rods in 3 or 4 point bending on a universal testing machine.

Properties of some common ceramics. Although standard test methods have been developed for rectangular specimens. The most common way of obtaining the flexural strength of a material is by employing a transverse bending test using a three point flexural test technique. The table below provides a summary of the main properties of ceramics and glass.

If the flexure strength is equal to 200 mpa at 50 survival probability what is the flexure strength level at which the survival probability is 90. σ 3lf 2bd in 3 point test of rectangular specimen σ 3fa bd in 4 point test of rectangular specimen σ 16fa πd 2fa πr in 4 point test of round specimen. As a result of the loading the specimen bends causing formation of in its convex side and compression stress in the concave side.