Aluminum Oxide Hardwood Floor Orange Oil

In fact it s said that it can add decades to the floor s color tone.

Aluminum oxide hardwood floor orange oil. Modern floor finishes oil vs. It s also used as a fortifier for urethane imparting hardness and abrasion resistant qualities lacking in polyurethane. An aluminum oxide definitely needs more work when you want to repair or rebuff. After the finish system is applied it is baked on to the hardwood in a specialized uv oven.

Aluminum oxide is a finish which is applied to wood products at the factory not on site after the floor is installed as is sometimes the case when finishing floors with urethane or oils. Before stripping the floors with regular wood paint or stain stripper learn about the differences between the types of flooring. For the last decades polyurethane with aluminum oxide has been and remains the standard bearer for wood flooring finishes whether factory finished or onsite sand and finish. Ao is the same material that is used to make sandpaper.

High abrasion finishes such as aluminum oxide may be difficult to sand. Urethane aluminum oxide consumers today have a great selection of hardwood flooring finish options. Unlike most other hardwood floor finishes penetrating oils don t leave a hard shell on top of the wood. Garrison also applies 9 to 11 coats of finish on every plank more than any of our competitors for ultimate strength.

During the manufacturing process the aluminum oxide and any final urethane finish are baked on with high intensity uv light creating a finished product. On the other hand any such minor maintenance damages to oil finished floors can be rectified. For this reason a final coat of wax often tops the oil for extra protection. When ground into a white powder it s used as a filler ingredient for paints plastics sunscreen and cosmetics.

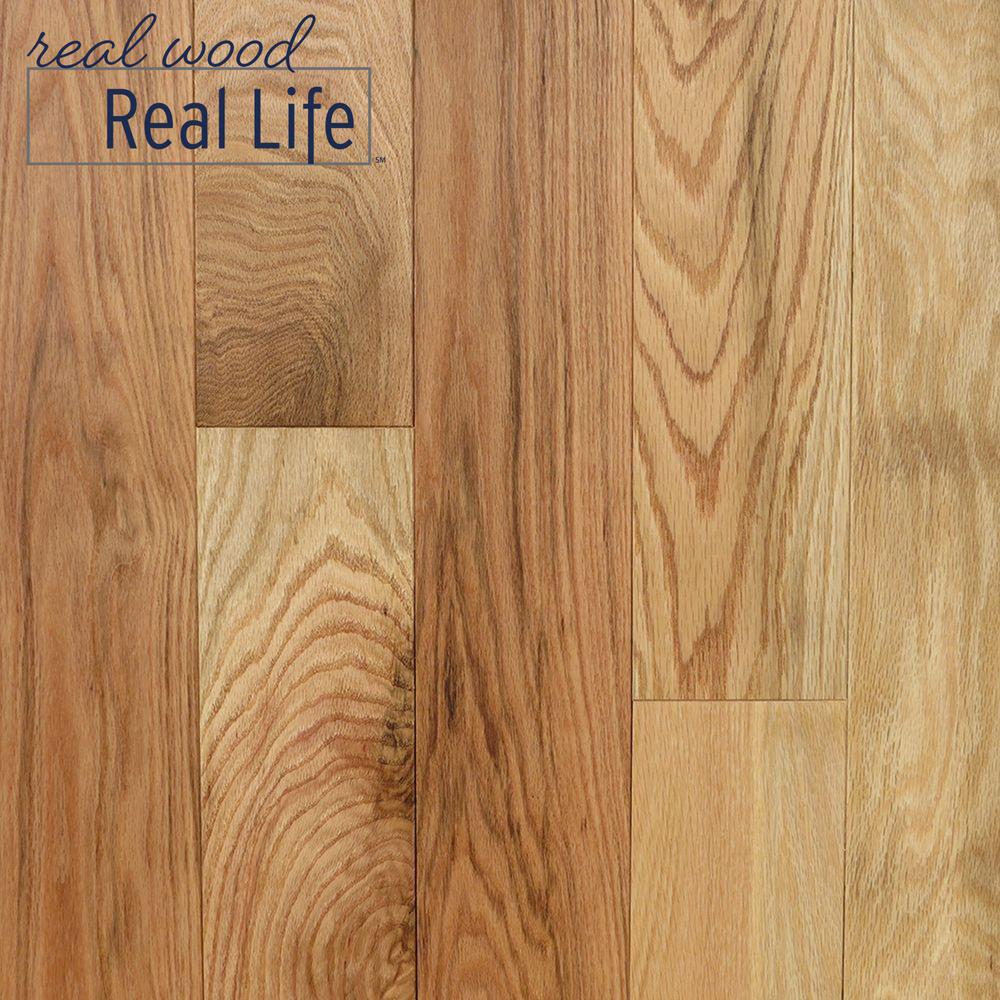

Aluminum oxide floors are traditional hardwood floors with a coating or sealant of aluminum oxide on top. You will have to move your furniture and empty the room entirely to apply an even fresh coat. High abrasion finishes may respond better by using a fine grit 80 grit or finer grit ceramic fired abrasive as the first grit used followed by a coarser grit to begin the upward grit progression to remove these surface finishes. It is a very tough and is added to the finish system to extend the durability of the urethane.

Modern hardwood flooring finish systems consist of several layer of urethane and aluminum oxide ao. Now fading is going to happen particularly rooms that get a lot of direct sunlight but the aluminum oxide finish helps negate the effects over time. Stripping and refinishing the floors as you would regular. An aluminum oxide finish is applied to the floor to slow the process of uv color fading over time as well.