Aluminum Oxide Ceramic Substrates

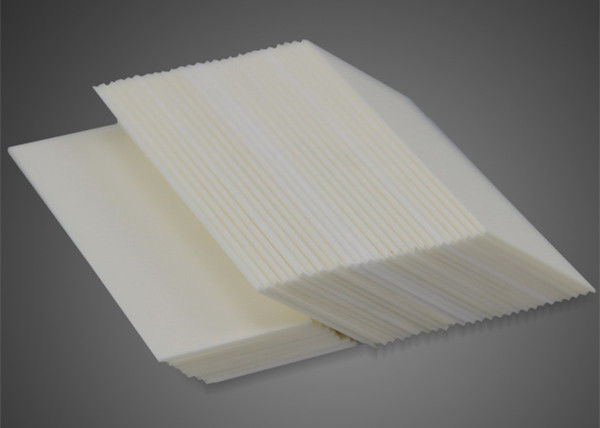

96 alumina aluminum oxide substrates and plates from stock 96 alumina al203 substrates plates and machined parts list of 96 alumina currently in stock as fired or lapped for thick film substrate applications and 96 alumina plates for machining including large geometry ceramics.

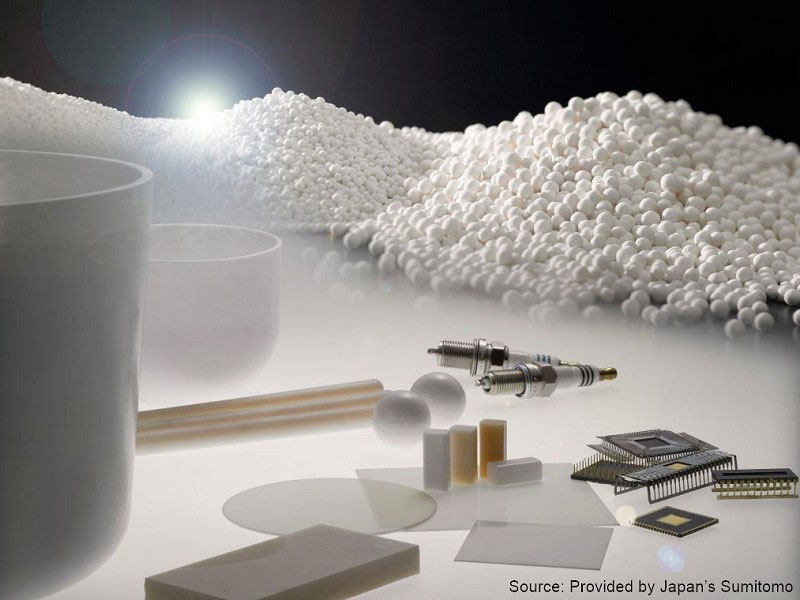

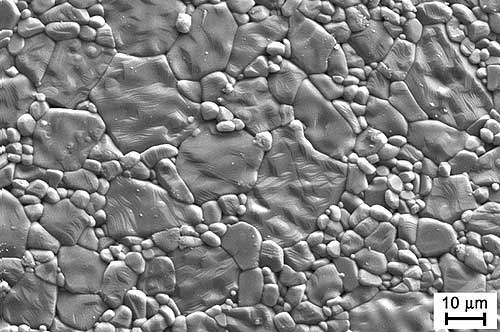

Aluminum oxide ceramic substrates. Alumina also known as aluminum oxide or al2o3 is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial medical and electronic applications. Science and technology 2001. Alumina is the most well known and most commonly used fine ceramic material. It has been used for decades in electrical components for its high electrical insulation and is widely used in mechanical parts for its high strength and corrosion and wear resistance.

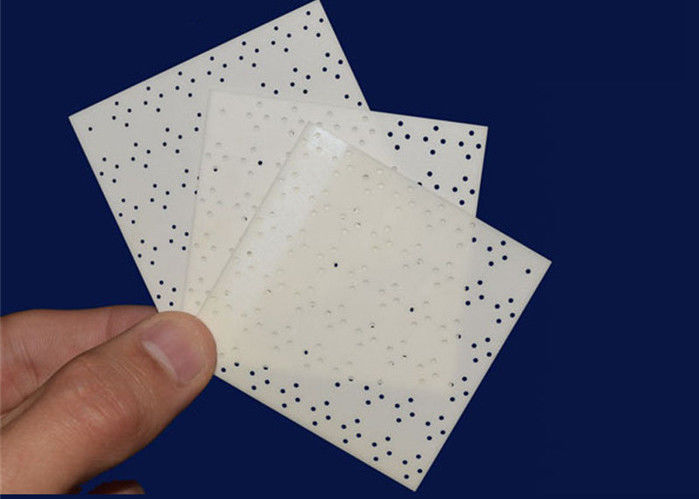

This is because alumina pcbs have good material properties including good thermal conductivity low cte coefficient of thermal expansion dielectric strength strong resistance to chemical hazards and hermeticity. It has the same sintered crystal body as sapphire and ruby. After firing flat substrates can only be precisely machined using laser or diamond methods. Our new dry pressing machines have higher pressure moreover automatically shaping multiple part with one die is also available.

Selection of purity alumina range from 95 to 99 7 alumina also deal with zro2 ceramic substrates silicon carbide substrates. We focus on manufacture a wide range of aluminum oxide ceramic substrates including. Ceramic substrates have a much higher thermal conductivity than pcb materials promoting transfer of the heat generated in the circuit to the outside where it may be safely dissipated. Low temperature co fired ceramics.

Nowadays unipretec is better at producing aluminum oxide plates al2o3 trays alumina plungers aluminum oxide tubes ceramic substrates cordierite parts zirconium oxide plungers zirconia pistons. Ceramic substrates and technical ceramics ceramics and ceramic substrates for thin film and thick film microelectronic photonic and electro optic applications. Aluminum oxide al2o3 or alumina 96 is the most widely used ceramic material for ceramic printed circuit boards and submounts. Examples of applications for aluminum oxide al 2 o 3 advanced ceramics are heavy duty forming tools substrates and resistor cores in the electronics industry tiles for wear protection and ballistics thread guides in textile engineering seal and regulator discs for water taps and valves heat sinks for lighting systems protection tubes in.