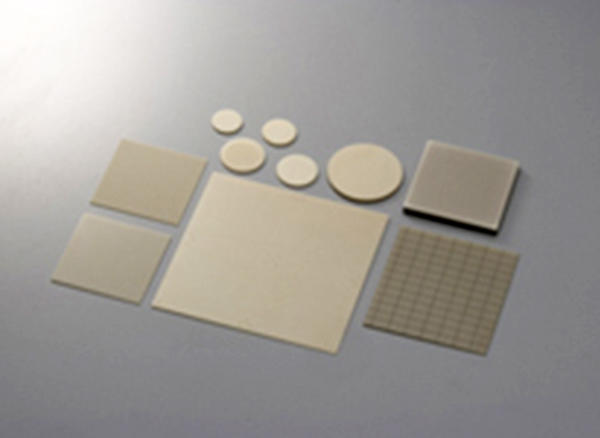

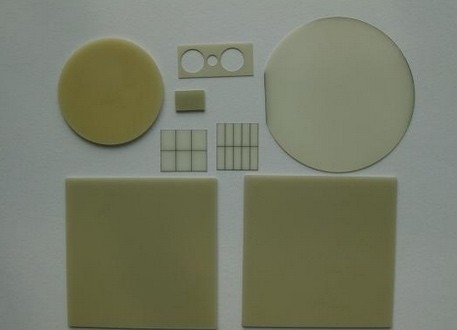

Aluminum Nitride Ceramic Wafer

Aluminium nitride has higher thermal conductivity compared to alumina substrate it is about 7 to 8 times high.

Aluminum nitride ceramic wafer. Aln substrate is one of the most popular ceramic substrate which has excellent heat resistance high mechnical strength abrasion resistance and small dielectric loss. Aln commonly comes in substrates up to 1 mm thick which can easily be laser cut. Wafers can be produced in various thicknesses and orientations with polished or unpolished sides and can include dopants. Aluminum nitride has a coefficient of thermal expansion and electrical insulation properties that closely matches that of silicon wafer material making it an useful material for electronics applications where high temperatures and heat dissipation is often a problem.

Aluminum nitride wafer brand name 3x ceramic parts material type aluminum nitride moq 5 pieces color grey light grey beige density 3 34 3 6g cm3 surface finish 0 3 0 5um main property high thermal conductivity thermal conductivity 165 185 w m k contact now. Swi provides aln ceramic substrate. American elements manufactures high purity single crystal aluminum nitride wafers for optoelectronics applications. Our standard wafer diameters range from 25 4 mm 1 inch to 300 mm 11 8 inches in size.