Alumina Ceramic Yield Strength

For full table with tesnsile strength compressive strength flexural strength and modulus of elasticity rotate the screen.

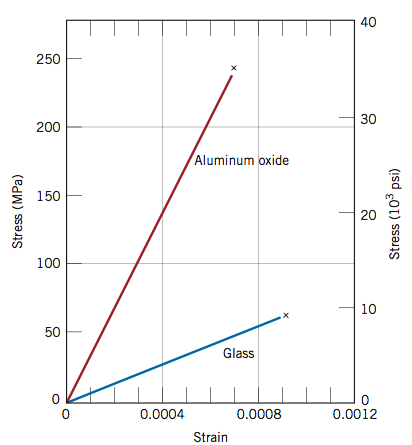

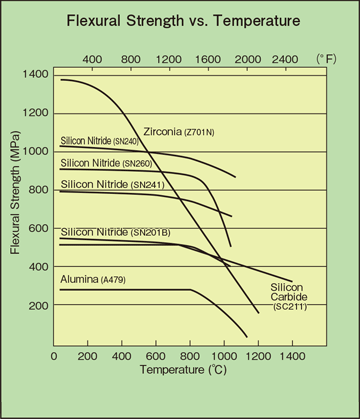

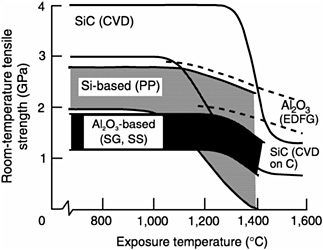

Alumina ceramic yield strength. Porcelain is a ceramic material made by heating selected and refined materials often including clay in the. Examples of two brittle materials that fracture before entering the plastic deformation region are aluminum oxide and glass as shown in the figure below. Alumina for example has a tensile strength of 20 000 psi 1138 mpa while the compressive strength is 350 000 psi 2400 mpa. 20000 45000.

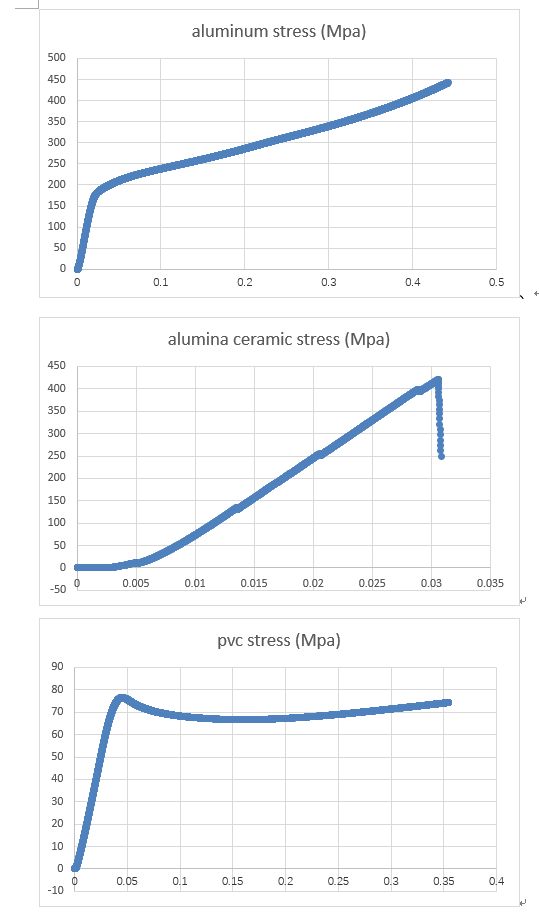

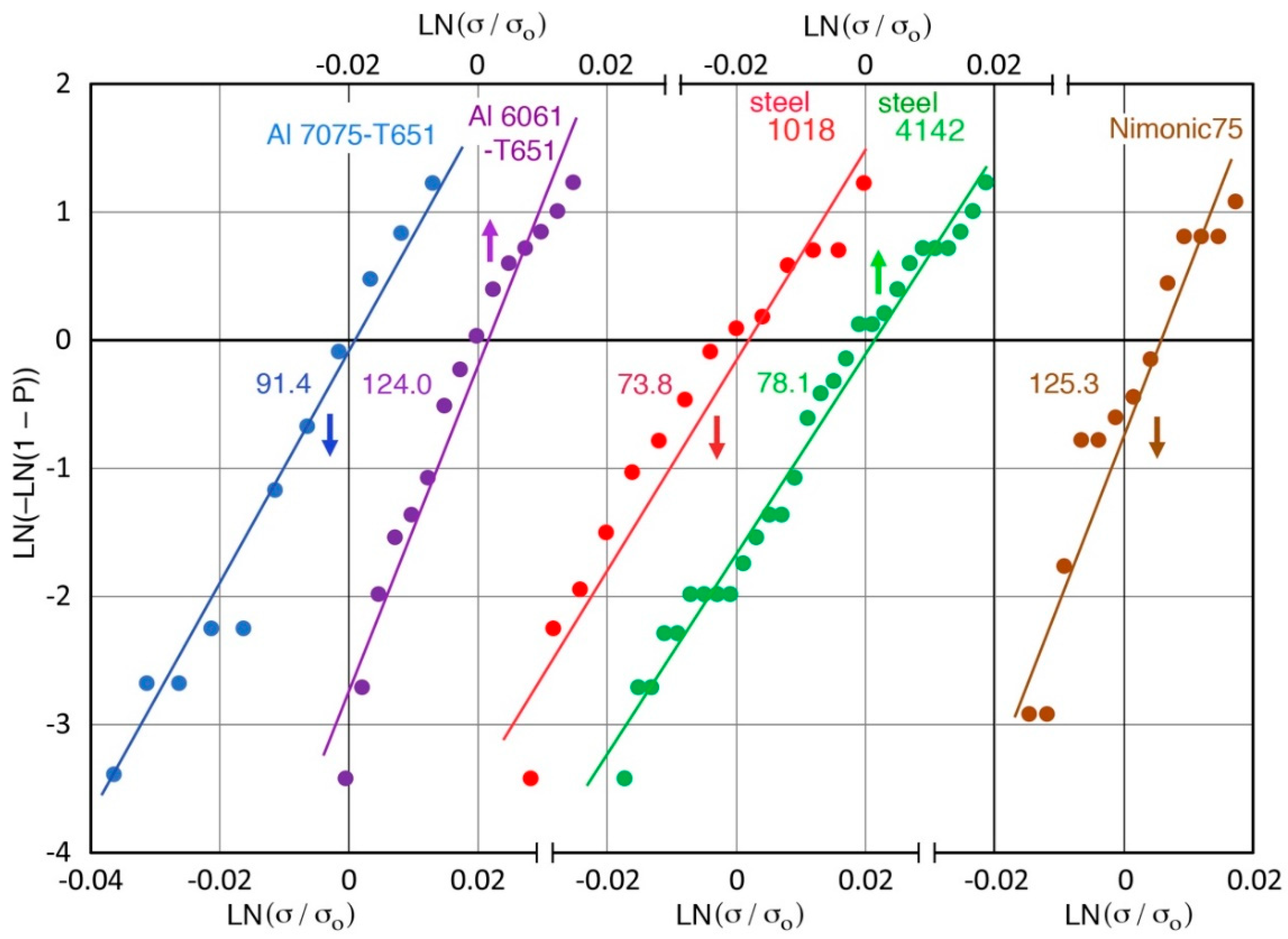

It is difficult to measure the yield strength of ceramics as they tend to fracture before they enter the plastic deformation region i e they are brittle. For a metal the compressive strength is near that of the tensile strength while for a ceramic the compressive strength may be 10 times the tensile strength. It has been used for decades in electrical components for its high electrical insulation and is widely used in mechanical parts for its high strength and corrosion and wear resistance. Machined or as printed and or geometry on the strength distribution is studied under uniaxial and biaxial bending tests.

The strength of 3d printed alumina parts fabricated using the lithography based ceramic manufacturing lcm technology is investigated. Alumina is the most well known and most commonly used fine ceramic material. The influence of the sintering parameters printing direction surface condition i e.