Alumina Ceramic V Alsic

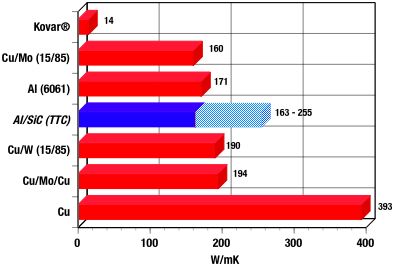

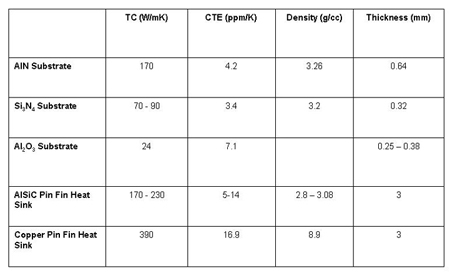

It has high thermal conductivity 180 200 w m k and its thermal expansion can be adjusted to match other materials e g.

Alumina ceramic v alsic. Easy to machine alumina bisque ceramic sheets. Fired at over 1600 c 2900 f to give a fully dense technical ceramic alumina exhibits high mechanical strength rigidity and can be machined to tight tolerances and fine surface finishes. The rockwell hardness of alumina ceramics is hra80 90. Drawing on over 35 years of experience we take pride in our high quality products custom designs and short lead times.

It has been used for decades in electrical components for its high electrical insulation and is widely used in mechanical parts for its high strength and corrosion and wear resistance. Alumina ceramic material is used to make high temperature crucible refractory furnace tube and special wear resistant material such as ceramic bearings ceramic seals and water valve sheets. Stc s fully dense 74 alumina to 99 96 alumina bodies are work horse materials for applications that require electrical isolation wear resistance high temperature resistance and good mechanical. Alumina ceramics are products made from the chemical compound with the same name alumina ceramic.

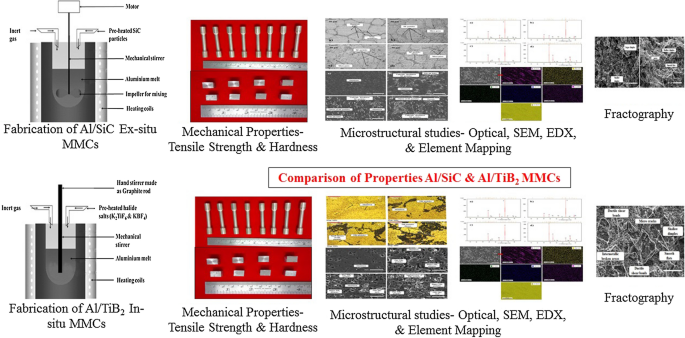

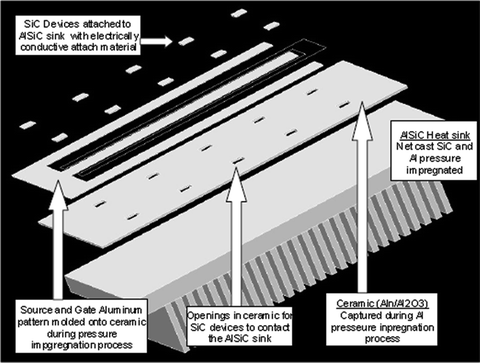

Alumina ceramic components inc. Thermal spray can apply alumina ceramic coatings directly to the alsic mmc baseplates. A reduction in process steps will lead to a reduction in manufacturing costs the main. Alumina is the most widely used technical ceramic and is the material of choice in about 80 of engineering applications due to its combination of properties.

Alumina ceramic also known as aluminum oxide is a combination of aluminum and oxygen. Alumina versatility stems from its broadly impressive material properties ease of manufacture wide availability and budget friendly cost. Acci specializes in manufacturing precision engineered dry pressed and machined ceramic components in various shapes and sizes and made to tight tolerances. Industrial ceramics alumina ceramics advantages and disadvantages.

Silicon and gallium arsenide chips and various ceramics it is chiefly used in microelectronics as substrate for power semiconductor devices and high. Alsic pronounced alsick is a metal matrix composite consisting of aluminium matrix with silicon carbide particles. We stand behind our products 100. Often used to create prototype components these ceramic rods come semi fired so they can be machined using conventional metalworking tools.

It occurs naturally most often as corundum as crystalline form of the compound that when gem quality manifests as sapphire or ruby. It is the most commonly used type of advanced ceramic and is available in purities ranging from 95 99 9. Alumina is an excellent high temperature ceramic material due to its high temperature stability. Alumina is the most well known and most commonly used fine ceramic material.