Alumina Ceramic Tensile Strength

20000 45000.

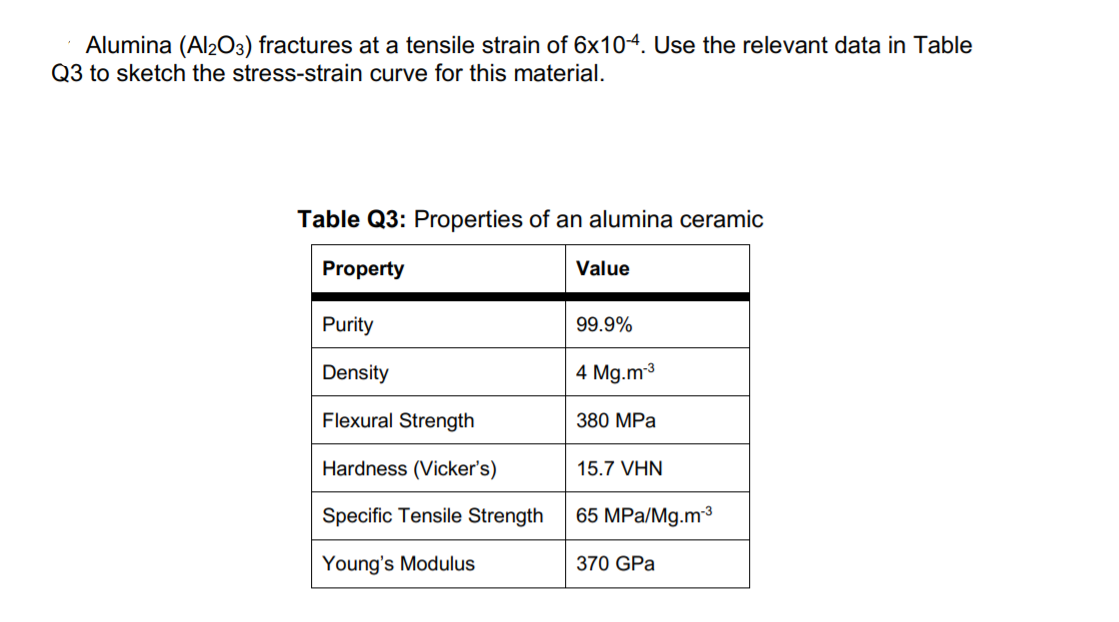

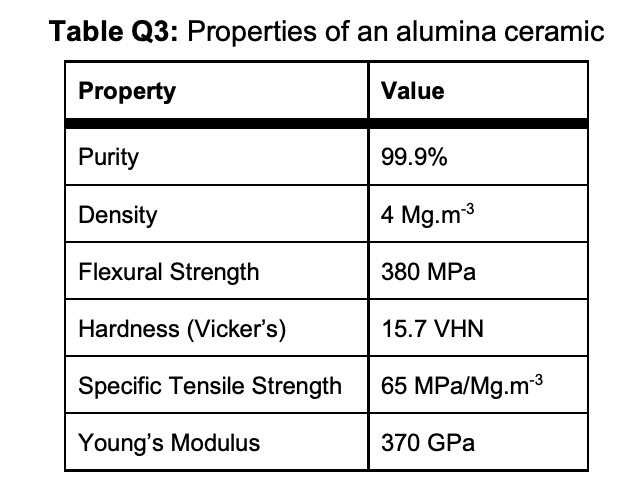

Alumina ceramic tensile strength. Variations are possible among various commercial grades. Modulus of elasticity young s. Property values below are taken from literature and manufacturer sources. Tensile strength σ psi compressive strength σ psi flexural strength.

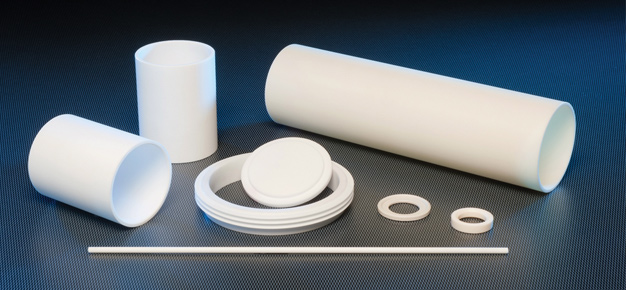

Alumina is produced by firing a tightly packed powder form of al 2 o 3 which includes some. We are always happy to use our many years of advanced ceramics experience to provide advice on materials design and application. It is ideal for applications that require dimensional stability high thermal stability and low thermal expansion in forms that can be made to. Aluminum oxide alumina is the workhorse of advanced technical ceramics.

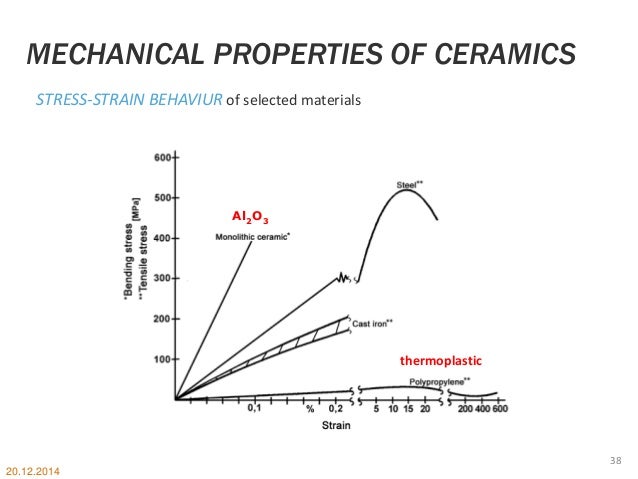

Ceramic to metal brazing threaded components precision motion components complex cleanroom assemblies thermal shock resistance tests are run by quenching samples into water from various elevated temperatures. For a metal the compressive strength is near that of the tensile strength while for a ceramic the compressive strength may be 10 times the tensile strength. Precision ceramics is your alumina machining specialist for your technical ceramic prototyping manufacturing needs. It has good mechanical and electrical properties wear resistance and corrosion resistance.

Porcelain is a ceramic material made by heating selected. Alumina al 2 o 3 is one of the most widely specified general purpose technical ceramics all aluminas are very hard and wear resistant with high compressive strength even against extreme temperatures and corrosive environments aluminas are also excellent electrical insulators and are gas tight. Alumina for example has a tensile strength of 20 000 psi 1138 mpa while the compressive strength is 350 000 psi 2400 mpa. Ceramics tend to be weak in tension but strong in compression.

Aluminium oxide al2o3 or alumina is one of the most versatile of refractory ceramic oxides and finds use in a wide range of applications. Alumina alpha al2o3 99 5 categories. The change in temperature where a sharp decrease in flexural strength is observed is listed as dtc. The raw materials from which this high performance technical grade ceramic is made are readily available and reasonably priced resulting in good value for the cost in fabricated alumina shapes.

Key features benefits of some advanced technical ceramics. Alumina is one of the most cost effective and widely used material in the family of engineering ceramics. Aluminum oxide al 2 o 3 ceramic properties.