Alumina Ceramic Tensile Modulu

Alumina alpha al2o3 99 5 categories.

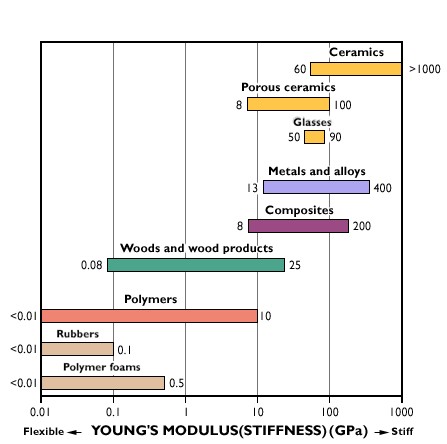

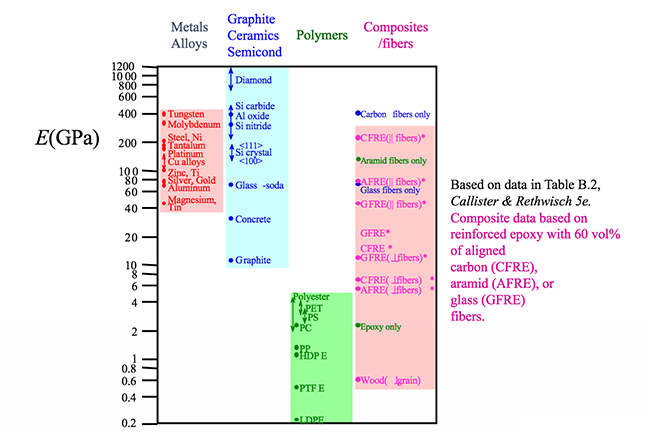

Alumina ceramic tensile modulu. The lower in the index the better the wear resistance. Rubbing tests are run using a dry 240 grit fused alumina abrasive. Modulus of elasticity and ultimate tensile and yield strength for steel glass wood and other common materials sponsored links tensile modulus or young s modulus alt. Young s modulus or the young modulus is a mechanical property that measures the stiffness of a solid material.

Aluminium oxide al2o3 or alumina is one of the most versatile of refractory ceramic oxides and finds use in a wide range of applications. Ceramic property values vary somewhat with method of manufacture size and shape of part. Once fired and sintered it can only be machined using diamond grinding methods. They provide high wear heat and corrosion resistance as well as high tensile strength volume resistivity dielectric strength and modulus of elasticity.

Material specific gravity sg coefficient of linear expansion α m m k maximum safe operating temperature o c thermal conductivity k 10 3 cal cm sec o c tensile strength σ psi compressive. Ceramic materials offer a number of benefits in a variety of applications. The properties of alumina include six common variations. Alumina is one of the most cost effective and widely used material in the family of engineering ceramics.

Property values below are taken from literature and manufacturer sources. Although young s modulus is named after the 19th century british scientist thomas young the concept was. Young s modulus or tensile modulus alt. Aluminum oxide al 2 o 3 ceramic properties.

Compressive strength flexural strength and modulus of elasticity rotate the screen. The indices in the chart are calculated by dividing the material volume loss by the volume loss of an ad 85 alumina control. This page shows summary ranges across all of them. Properties of some common ceramics.

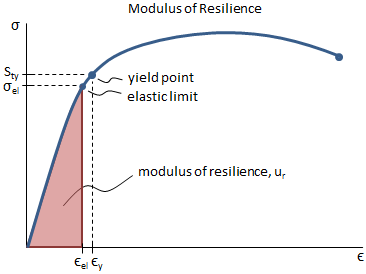

Modulus of elasticity is a measure of stiffness of an elastic material. For more specific values follow the links immediately below. It can have a fairly high thermal conductivity and a moderately high heat capacity among oxide based engineering ceramics. It defines the relationship between stress force per unit area and strain proportional deformation in a material in the linear elasticity regime of a uniaxial deformation.

Variations are possible among various commercial grades.