Alumina Ceramic Resistivity

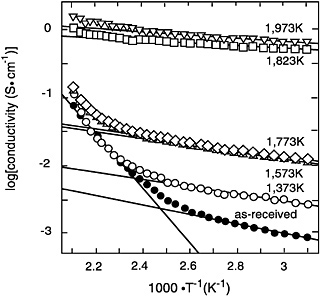

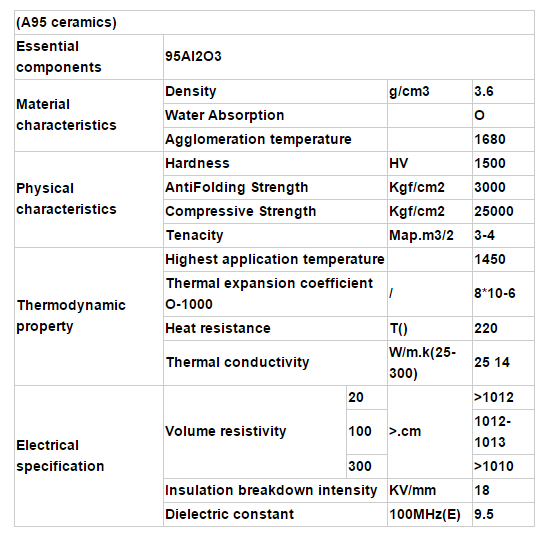

High purity alumina advanced ceramics 94 have the highest resistivity values 1 10 14 followed by aluminium nitride 1 10 12 sintered silicon nitride 1 10 10 and zirconia 1 10 9.

Alumina ceramic resistivity. Electrical insulator alumina is commonly used as a high temperature electrical insulator particularly the higher purity grades which offer better resistivity. Moreover one of the unique properties is its surface roughness. It is ideal for wear resistant inserts or products. Ceramic engineers can finely moderate both the chemical and thermomechanical properties of alumina ceramics using a choice of additives and bonding.

This is a top quality alumina ceramic of 97 6 al 2 o 3 content widely used for high integrity components where its exceptional electrical and thermal properties are essential to operational stability and reliability. Alumina has an electrical resistivity of about 1x10 14 ω cm. It has good thermal conductivity and can reduce thermal shock resistance. Maruwa has produced alumina al 2 o 3 substrates for over 40 years under severe quality control with carefully selected high purity ceramic materials that ensures stable quality and excellent properties.

Silicon carbide is the least insulating ceramic with resistivity of around 1 10 6 or even less for certain forms of cvd sic. Abrasion resistant alumina is a very hard ceramic and is excellent at resisting abrasion. Our alumina substrate has well balanced properties of insulation thermal conductivity and breaking strength. Aluminium oxide al 2 o 3 is the most popular technical ceramic in use today offering unbeaten price to performance characteristics in a wide range of application areas the appeal of alumina largely stems from its extreme versatility.