Alumina Ceramic Green Body Fabrication

The mechanical strength of the dry body is 8 0 2 4 mpa.

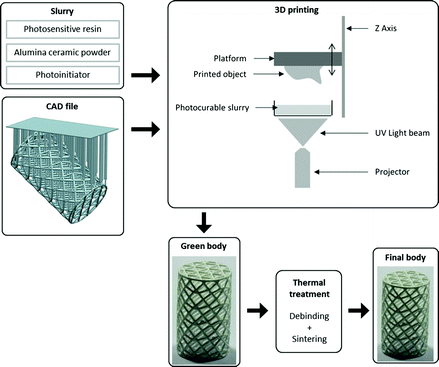

Alumina ceramic green body fabrication. The alumina ceramic green body fabricated by the present process has precise size and smooth surface. A customised 3d printer using a digital light processing dlp projector as uv source has been built to fabricate green bodies from photosensitive resins loaded with 25 60 wt of alumina 3 and 8 ysz. In this work we investigated two green ceramic forming processes i e. S1 shows the 3d printer autoceram beijing ten dimensions technology co ltd used in this study.

A green body with sufficient strength is formed removed from the mould and sintered to form a dense ceramic part. 4 the linear drying shrinkage of the green body is 2 3. The alumina green body was ob. While in the green or biscuit form it can be machined relatively easily into complex geometries.

Alumina can be machined in green biscuit or fully dense states. This would solve problems in existing applications and could. However the sintering process that is required to fully densify the material causes the alumiuna body to shrink approximately 20. Protein coagulation casting pcc and gelforming to fabricate 3d net shape ceramics via green machining and demonstrated their potential applications for the rapid fabrication of ceramics in some one of a kind biomedical applications such as dental restoratives and patient.

The final data was then imported into the stereolithography machine. Fabrication of the ceramic parts through stereolithography the 3d model was created using the ug software and then the magics software was employed to generate the supporting struc ture and to slice the parts. A stereolithography based additive manufacturing technique has been used for the fabrication of advanced ceramics. Green bodies were provided by tsinghua university and a detailed preparation process can be found in another paper.

The irradiation source was a 405 nm led. Sem shows that the microstructure of the green body is homogenous and compact without apparent agglomerate or pores. Aluminum oxide ceramic 3d printing at present there are only two major machine suppliers for the 3d printing of technical ceramics on the market lithoz which developed the lcm technology based on photo crosslinkable polymers and the company 3dceram which uses the same physical basis for the laser based stereolithography process for.