Alumina Ceramic Disc Manufacturing Process

At present there are only two major machine suppliers for the 3d printing of technical ceramics on the market lithoz which developed the lcm technology based on photo crosslinkable polymers and the.

Alumina ceramic disc manufacturing process. Prices of alumina have soared by 56 on the back of shutdowns in china with experts predicting the high purity alumina market will see a 16 7 cagr between 2016 2022. The advantage of the alumina ceramic parts products. But at present there are some problems in the production of alumina ceramic substrate in china such as the high sintering. Various quantities of non toxic monomer 2 hydroxyethyl methacrylate hema was added to form porous alumina ceramic by gel casting process.

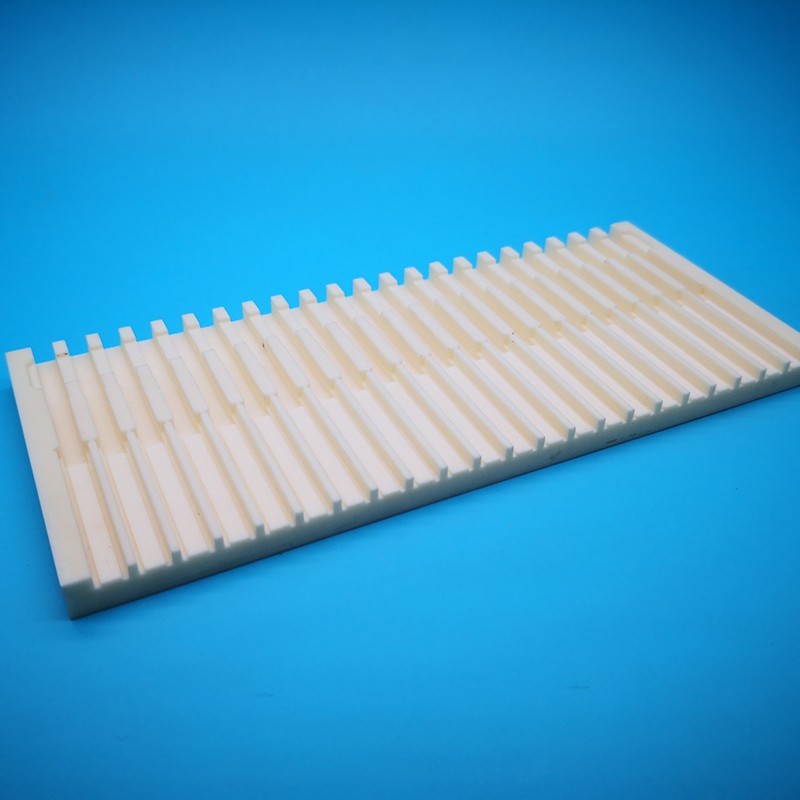

In this video you can see the manufacturing process of ceramic materials. Alumina ceramic substrate is widely used in multilayer wiring ceramic substrate electronic packaging and high density packaging substrate due to its high mechanical strength good insulation and light proof. Alumina can be machined in green biscuit or fully dense states. Raw material processes forming processes sintering diamond grinding optional inspection each of these stages in the manufacturing process with the.

Pure water monomer cross linker n n methylene bis. Manufacturing advanced ceramics the process steps in the manufacturing of advanced ceramics such as silicon nitride and sialon alumina zirconia and sintered silicon carbide are summarised in the flow diagram below. Alumina ceramic is a kind of ceramic material mainly composed of alumina al2o3 alumina ceramics have good conductivity mechanical strength and high temperature resistance and other capabilities. Alumina ceramic substrate overview of manufacturing process.

The bayer process is the principal industrial means of refining bauxite to produce alumina. Alumina synthetically produced aluminum oxide al2o3 is a white crystalline substance that is used as a starting material for the production of aluminum metal. However the sintering process that is required to fully densify the material causes the alumiuna body to shrink approximately 20. The world wide production is close to 90 million tons of alumina per year.

While in the green or biscuit form it can be machined relatively easily into complex geometries. Alumina machining grinding. Alumina or aluminum oxide al 2 o 3 is a chemical compound primarily known for its use in the production of aluminum a metal slated for significant growth in the advance toward a low carbon economy.